As dry excavation has grown for underground utility applications, the need for a specialized tool to meet safety and other concerns has become more acute. Given the potential hazards and costs associated with excavation of underground lines, Guardair Corporation drew upon expertise from utilities across the US to design the Utility AirSpade. Their concerns included:

- Maximizing digging efficiency of the tool

- Eliminating potential for spark-induced accident

- Optimizing human factors and safety

- Providing protection from high voltage, underground electric lines

Maximizing Digging Efficiency

The key to maximizing digging efficiency is the design of the output nozzle. Proper nozzle design starts with an in-depth understanding of the effects of directing compressed air into soils.

Soil is an unconsolidated assemblage of solid particles including clay, sand, silt, rock, and sometimes organic matter. Voids between the particles are occupied by air and/or water. When compressed air is directed into soil at close range, it enters the voids, expands, and fractures the soil in a fraction of a second. Non-porous materials such as metal or plastic pipes, cables, or even tree roots are unaffected.

To optimize nozzle performance, Guardair engineers recognized the importance of maximizing the exiting air speed (and subsequently the force) and tightly focusing the exiting air jet. This led to the development of the AirSpade Supersonic Nozzle, which converts compressed air into a high-speed, highly focused air jet moving at twice the speed of sound – Mach 2.

Equipped with the Supersonic Nozzle, AirSpade performs better in compact soils, provides faster excavation rates, and operates more efficiently by consuming less (expensive to produce) compressed air, thus saving time on the job site compared to other air excavation tools equipped with conventional nozzles. With a documented excavation rate of 1.0 to 1.5 cubic feet per minute (depending upon soil strength), the AirSpade is 2 to 3 times faster than hand digging and is highly effective in time-sensitive projects, while still protecting underground utility lines.

More efficient usage of compressed air also reduces air compressor operating hours. This translates directly into lower fuel costs and less wear and tear on the air compressor.

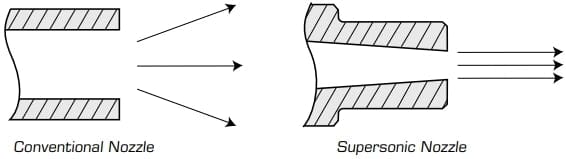

AirSpade Supersonic Nozzle:

Soil fractures from stress (force per unit area) applied to its surface. Focusing this force on a small unit area results in faster, and more efficient soil excavation. As shown in the diagrams below, air exiting from an open pipe, or from a conventional nozzle, expands rapidly outward, across 3 to 4 times the unit area, versus the focused output of the Supersonic Nozzle. In addition, open pipes or conventional nozzles operate at speeds below Mach 2. Thus, the Supersonic Nozzle outperforms these by a wide margin.

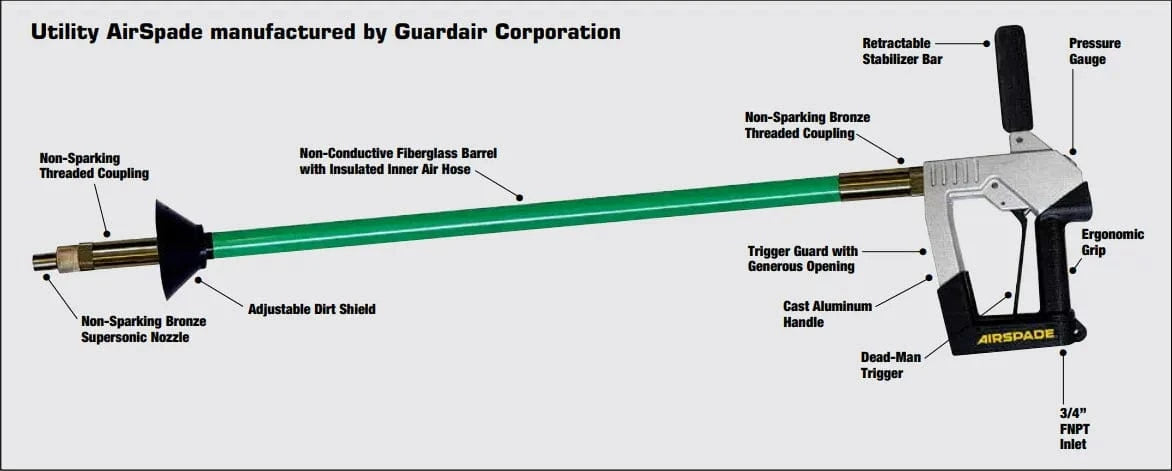

ELIMINATE POTENTIAL SPARKING

The need to avoid sparks in a potentially flammable environment, such as within a utility trench while exposing a natural gas line, is easy to understand. Sparks, generated by “friction” can commonly occur when some metals impact each other, or impact other hard materials such as rocks, or concrete. Unlike ferrous-based metals – containing iron (such as steel) – bronze does not generate sparks upon impact and is considered to be “non-sparking” in nature. To eliminate this concern, Utility AirSpade features a bronze Supersonic Nozzle and bronze barrel couplings.

HUMAN FACTORS AND SAFETY

Properly designed air excavation tools must incorporate ergonomic features, be easy to use, and, above all, be safe.

The Utility Air Spade handle has been designed to comfortably fit the hand and features a hand opening large enough to accommodate lineman gloves. Besides housing the dead-man trigger, the handle body also functions as a trigger guard to prevent accidental activation. When desired, a retractable auxiliary handle provides positive, twohanded control.

Finally, compressed air is a powerful, yet potentially dangerous utility, so the Utility AirSpade has been engineered to handle high-speed air flow of Mach 2, as well as air pressures up to 150 psi.

Protection From High Voltages

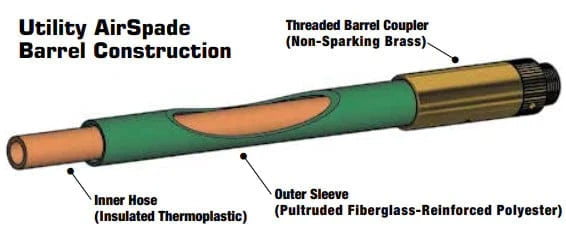

When excavating in the vicinity of underground utilities, the potential exists to uncover and expose high-voltage electrical lines. Consequently, to protect workers at the job site, the Utility AirSpade features an insulated fiberglass barrel assembly – incorporating a high-dielectric fiberglass outer barrel and an insulated inner air hose. Together, these components provide an electrical insulation rating of 75 kV per foot.

Utility Airspade Development

To meet these requirements, Guardair Corporation developed the Utility AirSpade incorporating the following features essential for the safe excavation of underground utilities:

- Heavy-duty, cast aluminum handle with full-size grip opening

- Retractable stabilizer bar for two-handed operator control

- Dead-man trigger with trigger guard prevents accidental activation

- Integral air pressure gauge ensures optimal operating performance

- Electrically insulated, 4’ fiberglass barrel rated to 75 kV per foot

- Non-sparking bronze barrel sleeves and threaded connectors

- Adjustable, dirt shield protects the operator from dislodged soil

- Non-sparking bronze Supersonic Nozzle

- ¾” FNPT air inlet

To learn more about the use of compressed air-powered excavation for utility/construction work, see the full Utility Technical Applications Bulletin.